31.01.2024

Estonian biotech start-up has developed a completely unique technology in the world

Estonian biotech start-up Gelatex specialises in the production of nanofibrous materials. The company was founded in 2016, but arrived at its unique technology and current line of business in 2020. Gelatex is a member of the Tehnopol’s Healthtech Community and the Innovation Leaders Club, they have also participated in the Startup Incubator’s accelerator.

The founders of Gelatex, Märt-Erik Martens and Mari-Ann Meigo Fonseca, met in 2016 in a University of Tartu laboratory. Märt-Erik was working with nanofibrous materials and the team set out to explore how these materials could be used in novel ways. When Mari-Ann – who was studying entrepreneurship and technology management – met the team, they came up with a leather-like textile together.

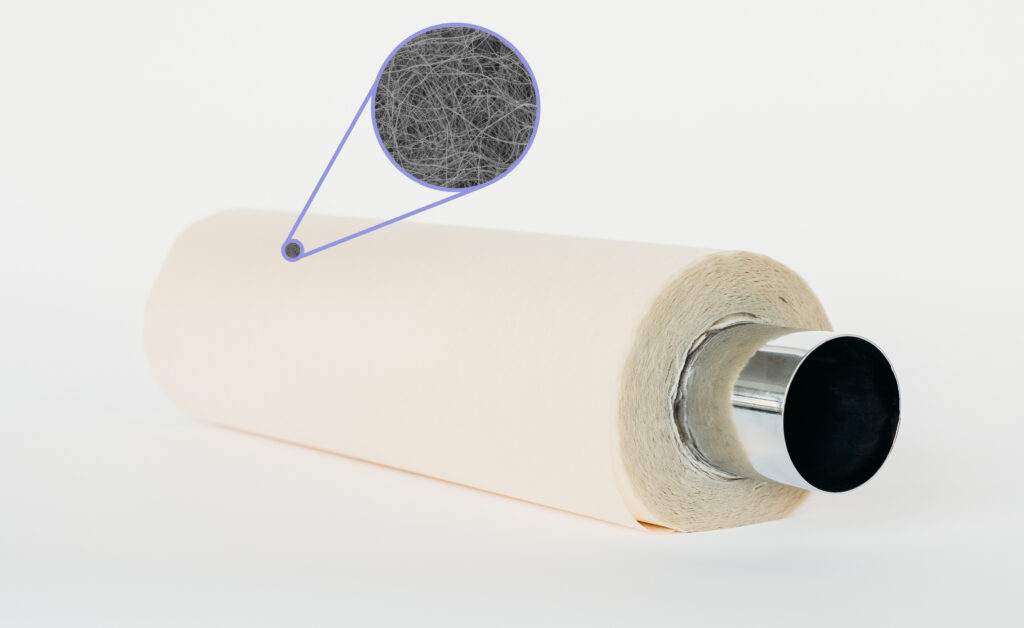

“One of the biggest challenges we had to solve was how to produce nanofibrous materials at a scale that would be relevant to the textile industry”, said Märt-Erik Martens. Before Gelatex’s technology, such materials were very expensive – a single A4-sized piece could cost up to €1000. However, Gelatex succeeded in developing a completely new technology called the halospinning, which allows nanofibrous materials to be produced in larger quantities than before. The produced materials are self-standing, i.e. they are not coated on top of another material, with the technology allowing for the creation of a much more porous material, which is very important for the company’s business today. They also filed a patent application in 2020.

In 2020, the company pivoted – they discovered that they were not utilising the full potential of nanofibrous materials. The leather-like textile is a thing of the past, with Gelatex having become a materials technology company that provides nanofiber materials to other companies for their services and products.

“We consider the beginning of today’s Gelatex to be 2021, when we raised our first major round of funding and began assembling our current team. While tech start-ups usually develop their technologies in universities and think tanks, we did it over the past 4–5 years within our own company. We deliberately did not raise any investments during that period, although we did have grant funding and various competitions, from which we raised the capital needed for development”, recalled Märt-Erik.

Unique technology in the world

“There are other companies around the world that offer nanofibres for growing cells”, said Märt-Erik. He added that nanofibres are nothing new by themselves, as they are produced using electrospinning technology that is over a hundred years old. “There are a number of companies around the world that are currently using this technology; however, the challenge is scalability and creating the most favourable environment for cell culture and tissue formation”, he continued.

In the case of electrospinning technology, cells are only located on the surface of the material. In contrast, Gelatex material is sufficiently porous for cells to migrate into the material and for nutrients to reach cells deep inside the material. This helps to form 3D tissue, so that cells are found not only on the surface of the material but also inside of it. “This is unique, something that conventional nanofibres are unable to do. This is also one of our key advantages in the Gelacell product segment”, said Märt-Erik.

To date, Gelatex has developed the world’s most powerful nanofiber production technology. “It’s odd to think about, but our small machine possesses a unique capability that allows us to produce nanofibres in much larger quantities and at a much lower cost than before. It is entirely unique in the world, and opens a lot of doors”, said Märt-Erik. The company’s mission is to develop materials that help cells to grow and tissues to form. This is important for wound care, for the pharmaceutical industry, and for the life sciences in general.

When it comes to the culturing of cells, for example, in drug development, Gelacell products developed by Gelatex are already in small-scale use and available on the market. According to Märt-Erik Martens, this product group is sold through distributors. There is not much of a market for the product in Estonia, although universities do use it in small quantities, with most sales being to foreign countries.

Another very strong segment is the cultured meat sector, as the future potential is to replace animal meat. “When cells are expanded, you get this kind of purée-like mass, and to give this mass the structure of meat, you need our materials”, he said.

Produces material for cooperation partners

Today, Gelatex’s future plan does not foresee them commercialising any products themselves, as they simply do not have the time to do so at the moment. “We are looking for cooperation partners with whom we can collaborate to bring new products or services to market”, said Märt-Erik. He highlighted a couple of wound treatment products currently in development with partners.

“Our goal is to enable the production of nanofibres for others who need it and who are in a much better position to bring these complex products to market”, he added. In the background, they are working on licencing their own technology and developing their own materials.

But what role will Gelatex play in the development of technology in the future? “I like to give the analogy that every major breakthrough in human technological development has come first through material innovation – we get to know, understand and manipulate new materials”, said Märt-Erik. The next big breakthrough could come in the field of synthetic biology, where mammalian cells can be grown and tissues formed on a larger scale, he says. Ideally, Gelatex nanofibres could be the very thing that makes it all happen. But there will certainly be other uses in the future that we cannot even think of today.